FAQs

General

I don’t buy bottles, I buy water for drinking and cooking

onshape.com, like fusion360 but works on Linux because it is browser-based

As soon as I find a way to do it in a useful way, I will do it

Ordinary 3D printers do not use much electricity, only about 50-150 Watts while printing, PETALOT use 60 Watts maximum.

BL sensor + hairspray + 60°C

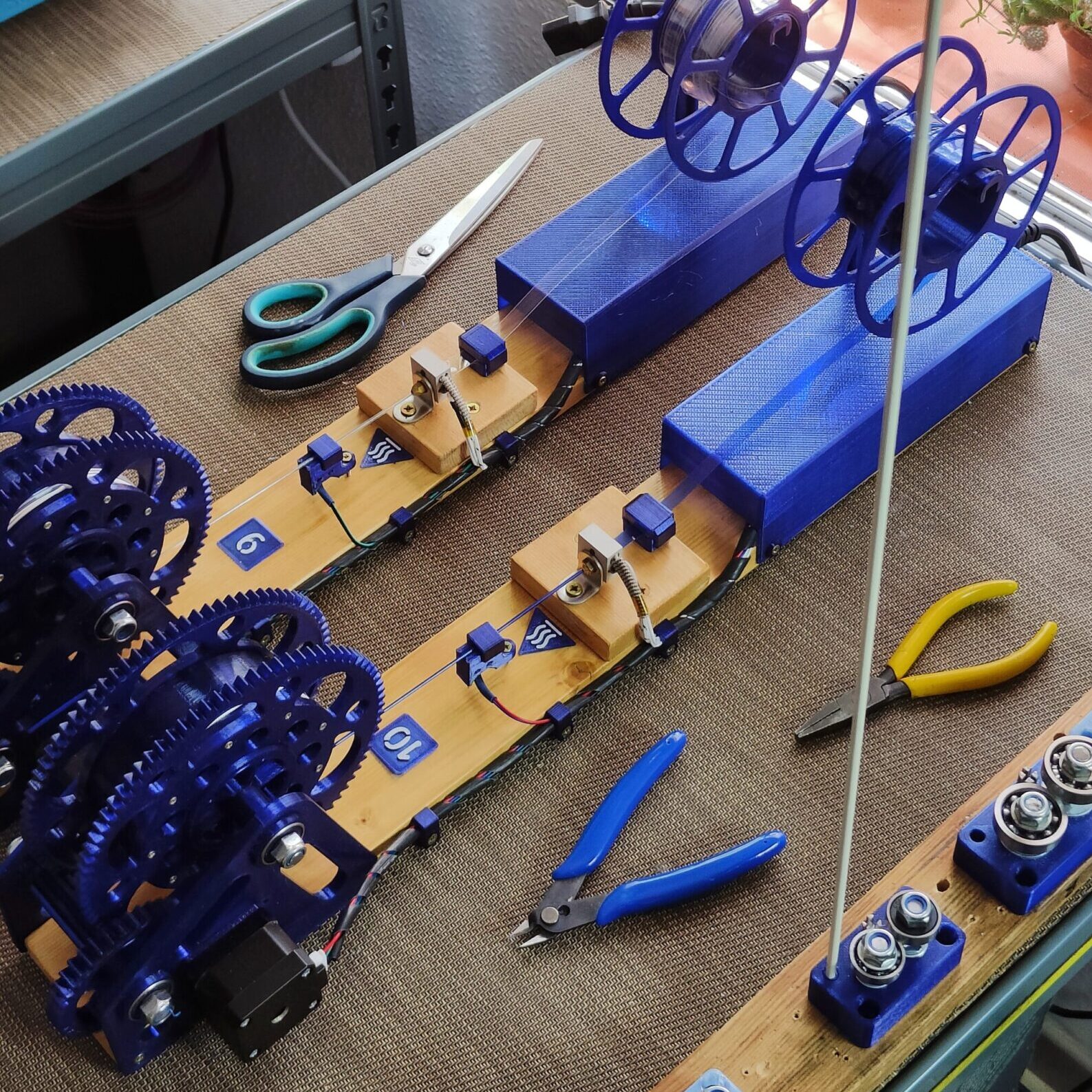

My 3D printer

Creality Ender 3, I bought it in December 2018 on aliexpress(order), it cost me 191€ with glass bed and 2 Kg of PLA as extras

https://www.tiktok.com/@function.3d/video/7128842620071054597?is_copy_url=1&is_from_webapp=v1

Today I use Mainsail instead of Octoprint, maybe tomorrow Fluidd or I go back to Octoprint

PETALOT

The idea is great but it’s not new, it’s not mine and it’s not easy to implement. The designs, plans, electronics and firmware that I share are my designs based and inspired by many other projects on the internet, the only right I reserve on my designs is the commercial use and attribution, you can distribute, mix, adjust and build from my designs as long as it is for personal use

The width of the cut depends on the thickness of the bottle wall, as a general rule:

Thickness Width

0.2mm 10mm

0.25mm 9mm

0.3mm 8mm

0.35mm 7mm.

With heat (220ºC) and force the PET plastic strip is bent into a straw shape, the plastic does not melt at any time when the filament is being made, only when 3D printing is when it melts at 255ºC.

220ºC and 20cm/min

The consistency of the filament depends on the consistency of the width of the plastic strip, the crucial moment on which the consistency of the filament depends is just during the cutting of the plastic strip from the bottle

I clean the plastic in all parts of the process conscientiously, before counting the bottle in strip I clean it with water and soap and with solvent if it has glue, then I keep the plastic strip clean of dust with cleaning filters even during the 3D printing.

PET fumes are, like PETG, harmless and odorless, also PET plastic is food safe

I use an ATX PC power supply, but 12V 60W should be enough.

From this premium 1.5L water bottle I get approx 25g or 10m of final filament, this is because these bottles have very little waste and a wall thickness of 0.35mm which allows me to cut them to 7mm width, do not expect to get more than 5 meters of filament from an ordinary 1.5L water bottle. Also these water bottles are not consumed by me, a neighbor brings me a few each week. I buy 8L bottles for drinking and cooking which give me 27m or 66g each.

From this premium 1.5L water bottle I get approx 25g or 10m of final filament, this is because these bottles have very little waste and a wall thickness of 0.35mm which allows me to cut them to 7mm width, do not expect to get more than 5 meters of filament from an ordinary 1.5L water bottle. Also these water bottles are not consumed by me, a neighbor brings me a few each week. I buy 8L bottles for drinking and cooking which give me 27m or 66g each.

The speed is between 16 to 20 cm per minute.

I get 25g of filament from a 1.5L water bottle and 25g of filament cost on Amazon about 70cent